The making of the New Best Upgraded / Improved Auto Switching Atari Auto switching 2600 Power supply.

Why has Best started to replace all of the stock linear (fixed US 110V) Atari Power supplies to the Newer Generation Auto Switching (110V / 220V 60Hz / 50 Hz) design, now the Power Supply Industry World Wide Standard? A single all in one Power Supply that can be used anywhere in the world. Here is a short list of the Best Atari 2600 Auto switching Power Supplies upgraded features:

1. Auto switching Power Supplies (PS) run much cooler compared to the old Linear designed (25 to 30+ year very very old PS design standard, different versions for each International Country) Power supplies that always run warm to hot. Any Engineer will tell you a Power supply that runs cooler will last longer, compared to the hotter running (over heats all of the electrical components inside the Power supply plastic case and accelerates their early failure) older linear Power supply design. In your recent history, can you remember when your new Auto Switching power supply for your smart phone, tablet or Bluetooth device ever failed? Usually the your I phone, smart phone, tablet or electronic device will fail, develop a problem or simply become obsolete before your new auto switching power supply for it would ever fail.

2. The newer designed Auto switching Power supplies are lighter in total ship weight, which means less shipping costs for Atari users.

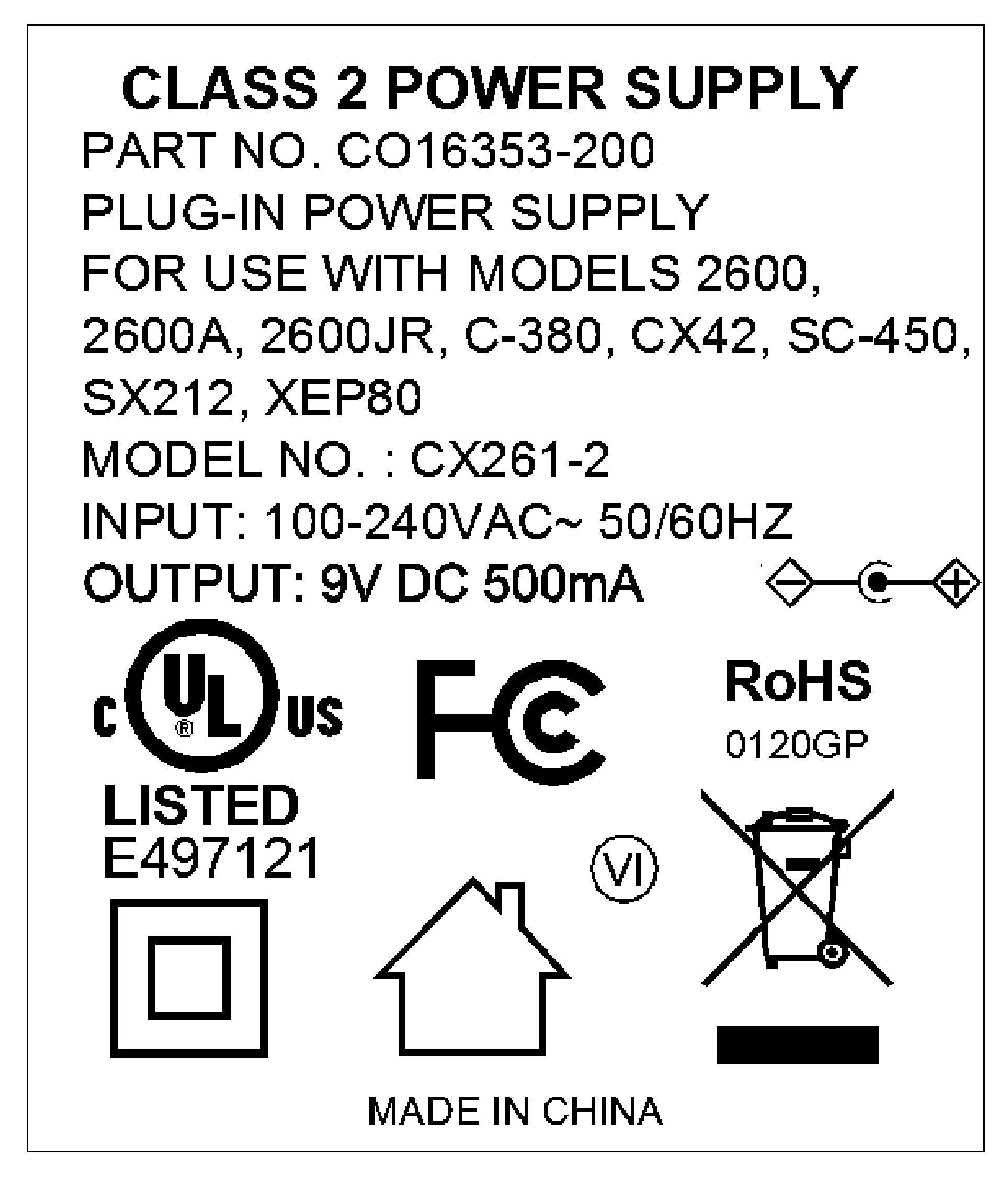

3. The newer auto switching power supplies are more efficient in their power usage. Example our last Atari US 2600 Linear power supply was rated at 7 watts power usage. Best checked about 10 to 15 old (5 to 25+ years old) Atari 2600 linear power supplies we had around the Best Atari warehouses. We also found a couple of the very very 1st Gary (an Atari rare collector item itself) heavy 6er 2600 OEM linear Atari Power supplies. The wattage usage on those very old Atari 2600 Linear Power supplies ranged from 9 Watts to a high of 12 Watts for the exact same Atari 2600 OEM 9 volt 500 MA power supply (just different Power supply manufactures supplied them to Atari). The New Best Atari 2600 Auto switching power supply is rated at 4.5 watts power usage (one of the reasons why it runs cooler) and has a VI / 6 (the latest and current standard US Power supply efficiency rating system) rating.

4. The new Best Atari 2600 Auto switching Powers Supply has the extra designed in Electrical / Electronic features of over Voltage protection, over Current protection, Short circuit output protection and input voltage protection, simply not available on the old / older made Atari 2600 Linear design Power supplies.

5. The new Best Auto switching 2600 Power supply is rated by our Power Supply manufacture for 20,000 continues operating hours (2.28 years of 24 hour continues operation) of total power supply usage, Mean Time Between Failures.

6. Best upgraded the stock OEM Atari 2600 Power supplies flat lead cable (just two bare copper wires extruded within a single thickness outer black jacket) to the much stronger design round Power supply cable (two separate plastic jacketed wires within a third extruded round outside black jacket / cover). Best has also Gold plated the male 3.5 mm power connector for better electrical conductivity. A few of the known 30+ years of failures of the Atari twin flat power supply cables. Exposed copper wires or broken internally copper wires (can not been seen on the outside of the flat wire ceasing) within the flat cable black plastic jacket where the flat cable goes into the back end of the 2600 power supply male connector strain relief body. The same exposed copper wires or broken internally copper wires as the twin flat cable as it goes into the power supply plastic case molded case strain relief body.

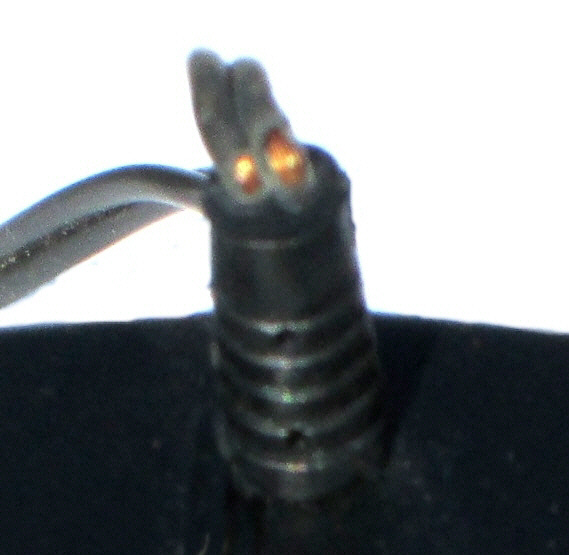

Close up view of the back end

of a 3 rib 2600 connector body.

Close up view of another different Atari OEM 2600 Power Supply 6 rib strain relief damaged cable.

Close up view of a different Atari 2600 Power Supply

5 rib strain relief damaged cable.

On the case of both exposed copper wires next to each other, eventually they would short together and damage / burn out the 2600 power supply internal electronic circuits. The second failure rate, you would playing your Atari 2600 console and it would all of sudden turn off / shut down. You would wiggle the old 2600 twin flat power supply cable (one or both of the internal wires have a broken copper wire within the Cable jacket (not visible from the outside cable jacket) as it goes into a molded on strain relief) and the Atari 2600 would start to work again, until you accidently moved / bumped the 2600 console again. Eventually the broken wire ends would short out enough internally to cause the outer black cable jacket to heat up and burn off with copper wires causing a burn hole in the outer flat wire jacket.

7. Each of the two new Best 2600 Auto switching power supply molded on cable strain reliefs (3.5 mm connector body and Power supply case itself) are required by Underwriters Laboratories (UL) Power supply standards to pass a 4 Kg (8.81 Lbs) pull test for 1 minute and show no damage to the cable body / jacket or molded on strain reliefs. Our Power supply manufacture says another cable test the Best Auto Switching power supplies are required to pass, is a strain relief stress / bend test. Each molded on cable strain relief (3.5 mm connector body and power supply plastic case strain relief) cable length is weighed down with a 300 g (10.5 oz) weight and then the cable is swing back and forth 90 degrees to the stationary molded on strain relief, 45 times per minute for over 1,000 cycles. The outer cable jacket and both molded on strain reliefs are to show no damage after this test. Also the two inner jacketed copper wires within the second outer extruded black cable round jacket are to show no damage or breaking of the inner copper wires as they go into both of the molded on strain reliefs.

8. During the manufacturing process the Best Auto Switching power supplies have to pass the UL required electrical HI Pot Test (applied High Voltage, 3750V AC, 50 Hz for 2 seconds) input to output test showing no shorting or break down of the power supply internal and external components like the round jacketed wires, solder joints on the 3.5 mm backside male connector and wire solder joints on the inside of the power supply PCB board.

9. Auto Switching Input Voltage operating rating of 100V to 240V AC 50 / 60 Hz input and 9 + - 5% VDC output voltage. Our power supply manufacture says it has a reliable input Voltage range of 90 to 264 AC 50 / 60 Hz, which means it can be used just about anywhere in the world.

10. Each New Best auto switching Atari 2600 Power supply has a longer 15 foot stronger round power cable (older stock Atari 2600 Linear Power supplies had a 10 to 12 foot twin lead flat power cable), with a New permanently attached (heat staked on) black micro Velcro cable wrap (1st used on the New Industry standard and very very popular Best Auto switching Atari 7800 Power supply) to the round power cable itself for easy storage of the used longer power cable length, if the full 15 foot length of is not required for your exact Atari 2600 console set up. A lot of the new non Atari made substitute / clone linear 2600 power supplies listed on E-Bay have a short 6 ft. power supply cable length and all have the known twin flat cables which will cause them to all fail early (see PS cable strain relief pictures above). Also many have a higher amp (600 to 800+ milliamps) rating, compared to the Atari Engineering 2600 Power Supply specification of max. 500 MA rating. The clone 2600 power supplies with the extra milliamps puts a greater stain / stress on the 2600 motherboard 7805 5 volt step down voltage regulator.

11. The Best Auto Switching 2600 Power supplies (Quality Assurance audited samples during production) are subjected to cable Flexing / Bend tests (around the molded on Strain reliefs), 6 Drop tests onto a hardwood floor from a .75 mm height on all 6 sides one time each and show no electrical, mechanical damage or cracks in the PS Plastic case. 20 minute Vibration tests on X, Y and Z axes and a 8 hour Salt spray tests and then 16 hour dry out period and show no degrading of the sample Power supplies during the production run of them.

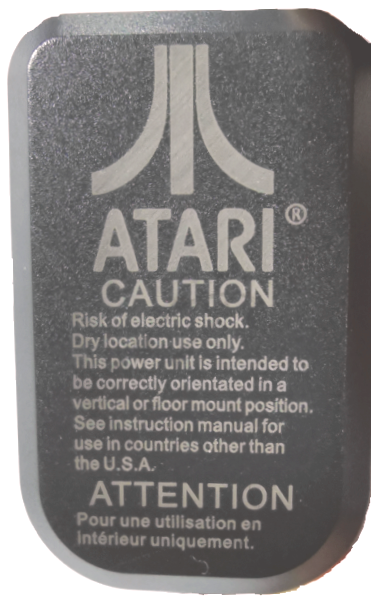

12. All front and back Best Auto switching 2600 Power supply case labels are permanently Custom Laser etched into the black Power supply plastic case surfaces vs most power supplies with either plastic or metal labels that can be easily damaged or fall off the Power case body so many years down line.

13. Each New Best Auto Switching 2600 Power supply finished lot / production run, is 100% factory burned in and Electrically / Electronically Tested / Monitored for 4 hours of use before they are packaged up and shipped.

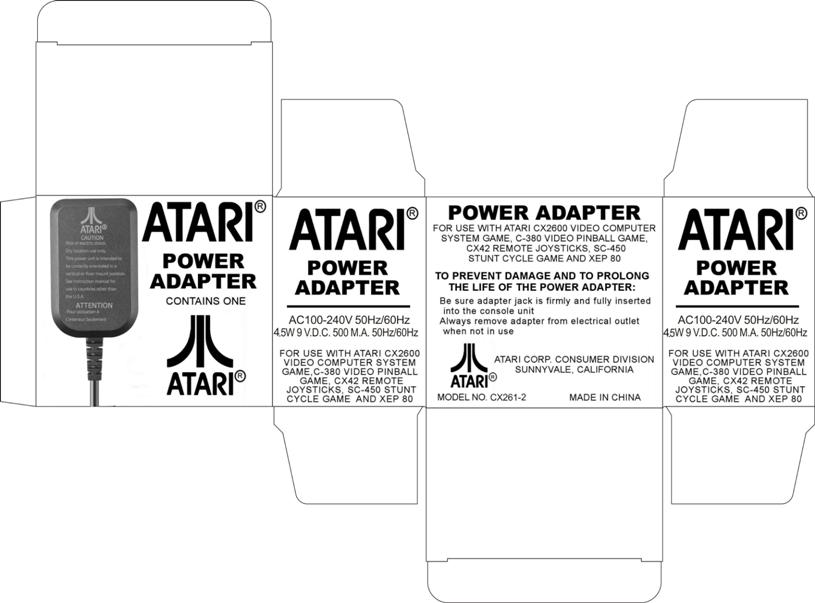

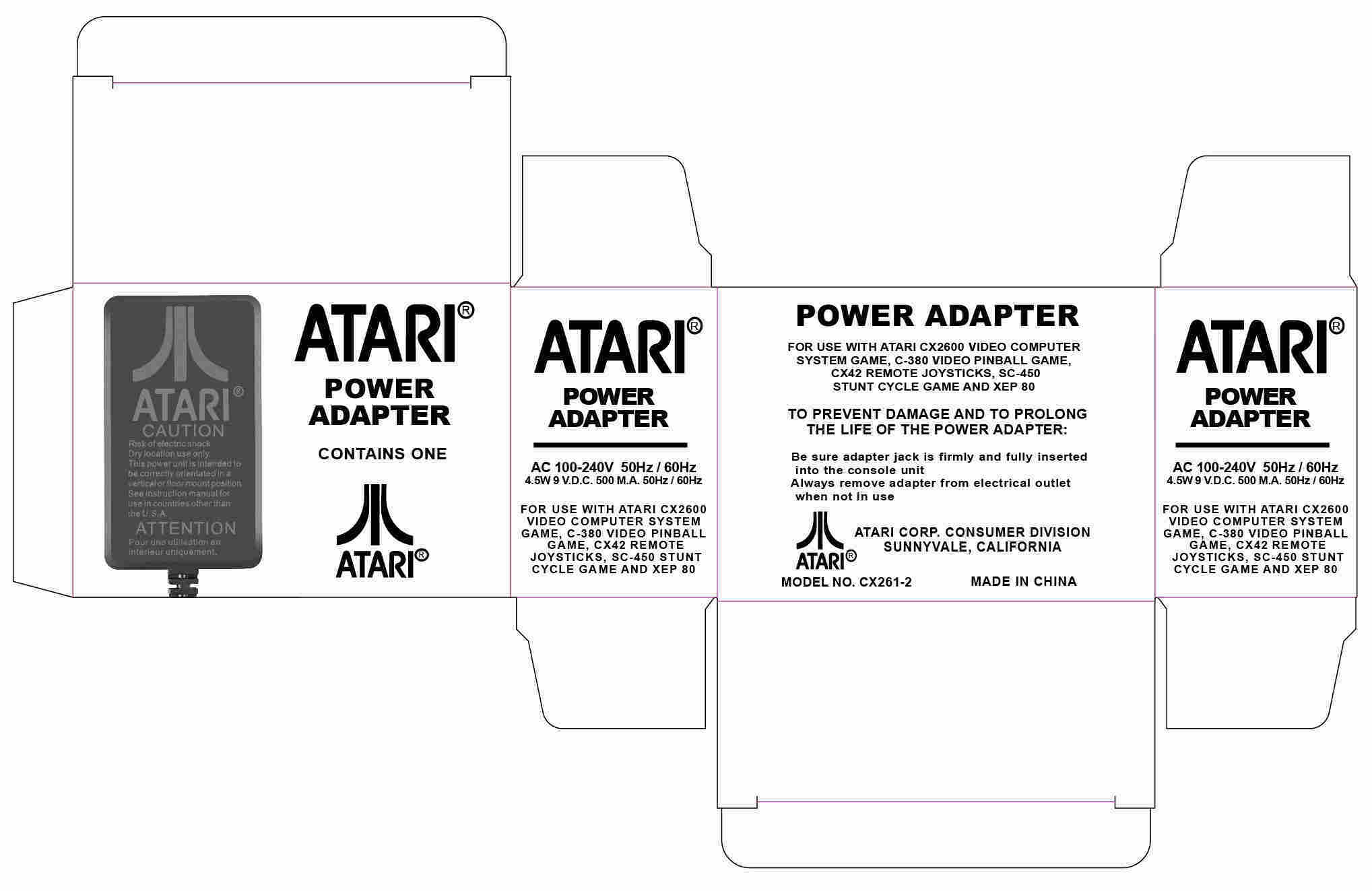

14. For the last 40+ years in the Atari Business, Best Electronics has never had any control over the quality of the Atari 2600 Power Supplies themselves and the Atari Power supply boxes we have sold. The Atari 2600 Power Supply boxes were so thin, that when shrunk wrapped, the boxes would start to bend / distort from the original box shape, collapse inward on the front / back / top and bottom sides of the boxes. Then when a new boxed Atari 2600 power supply was shipped across the US, the Atari 2600 PS boxes it would get easily damaged or end up looking poor condition when received. When Best opened up a new Master Carton (after they had been shipped from the Far East to Atari Sunnyvale warehouses) of Atari 2600 Power Supplies, the black printing on the sides of the 2600 boxes had smudged / rubbed off onto the other white new Power Supply boxes in the master carton, making them look poor. Best asked our new Power Supply manufacture to triple the thickness of the new Best 2600 auto switching power supply display cardboard box thickness / walls and after the sides of new boxes were printed, that the box manufacture put a clear coating on the outside of the boxes to prevent the black printing from rubbing off / smudging the other 2600 Power Supply boxes in the master carton of them when they were shipped to Best.

Best 2021 Auto Switching Atari 2600 Power Supply Model CX261-2 CO16353-200 $13.95

Best knew that early in 2017 that sometime in the future we would finally sell out of the Atari OEM made 2600 Power supplies we have been selling for over 10+ years. We did finally run / sell out of them mid. September 2019. Early January 2017 Best started to search for a New Power Supply manufacture. As we have always done for the 36 years in the Atari Business with all of the New and Upgraded Atari products we have developed / made, we know we could make a much better Enhanced / Upgraded / State of the art version of the Atari OEM 2600 power supply and fix the 25+ years of known problems on the stock Atari made 2600 Power Supplies that caused them to always fail early.

Daniel G. of MA. Daniel purchased Bests new Upgraded / Enhanced 2600 Auto Switching power supply and a new Atari PAL 2600 32 in 1 game cart. "I just wanted to express my satisfaction with my order and prompt delivery. Your 2600 Power Supply has eliminated the wavy lines on my screen! I have even done a full recap, 6 new switches (ordered from you last year or so), and voltage regulator previously but it seems like the cheap 3rd party adaptor I was using was the worst culprit! Also despite being a PAL cart the 32-in-1 unexpectedly works fine on new 2600+ on flat screen."

So started Bests 2 year 12 month search for a new Power supply manufacture that could meet our new Atari 2600 stringent Power Supply Requirements and Specifications. We put out a general cattle call for Power Supply manufactures to contact us regarding our Power supply requirement. About 25 to 30+ Power Supply manufactures contacted Best. We sent them our Engineering specifications for the New Atari 2600 Power supply. About 20 Power Supply manufactures responded back to us but could not meet all of our Power Supply requirements. After 2 to 3 weeks of back and forth with all of them, one by one they were dropped. For the next month or so, Best spent talking to the remaining Power Supply manufactures, making sure they could meet all of New auto switching 2600 Power Supply requirements. Of course all said they can meet all our Power Supply requirements we sent them. Weeks and weeks of more back and forth correspondence with each Power supply vendor, one by one they would be dropped by Best because they could not meet one or more of our Engineering Specifications. When really pressed hard or asked to show us some samples Power supplies they have made for other customers that have the exact features we required more dropped off the list.

One of the very early Power Supply manufactures that contacted Best, thru up red flag here. Best noticed they kept using different UL Power listing numbers (which are unique to a single Power Supply manufactures model) on each different Power Supply label artwork samples they sent us. When Best checked the different UL listing numbers with the UL listed / approved Power Supply manufactures list, all of the UL listing numbers they give us, ended up being a completely different Power Supply manufactures UL listing numbers and not the power supply company that contacted Best. Best concluded this Power supply manufacture was not a real Power Supply manufacture, but a jobber (general supply company) that had different Power Supply manufactures make Power Supplies for them and resale them to their end customers. They acted like a Power supply Manufacture, but did not the have the different Power Supply features Best required and the different Electrical Certifications like UL (US), cUL (Canadian UL), FCC and ROH. Over the years Best has run into many many Far East suppliers like this company. It has never worked out with any of them and always ended with Best not getting all of the Atari product features we required from the jobber / company who was trying to save money (because of Best required feature would cost them more) and they would make less profit on that Atari product.

German Atari OEM 2600 Linear 220V Power supply with the flat twin cable that fails.

Another Cattle call to Power supply manufactures, again about 20+ manufactures contacted Best. Again it took about a month and half to sort thru all of them. One new Power Supply manufacture seemed to be the best of the best of the ones that contacted Best. They said they could meet all our New 2600 Auto Switching Power supply written requirements we sent them. We arranged to ship ($$) them 3 to 4 different old Atari 2600 Power Supplies and display boxes made in the last 20+ years. After 2 weeks after we shipped them the Atari 2600 Power Supply samples, the new Power Supply Manufactured E-Mailed us saying they have not received the sample 2600 Power supplies we sent them. We E-Mailed them the package tracking number. It seems this new inexperienced Power Supply manufacture was located in the middle of nowhere. They did not even know how to properly track down our missing our power supply package in their area. A few E-Mails back and forth, Best concluded this was a new Power Supply Manufacture had little experience dealing with International Power supply orders. They basically said they could meet all of our New 2600 Power supply requirements, but really did not have the Power Supply manufacturing experience to handle our Power supply requirements. So Best had to give up on them and again begin another search for a new Power Supply manufacture. By the way, toward the end of 2018 (6 to 8 months after the Power supply samples were 1st shipped out) Best finally got back a empty shipping pouch with all of the sample Atari 2600 Power supplies and boxes missing from the package. Of course that long time frame was past the required time we could put in a claim for missing lost Power supplies and sample boxes.

More months of new general Cattle calls to new Power Supply Manufactures resulted in more Power supply vendors to spend months sorting thru but no vendors we could work with. Coming now down to the end of the 2018, Best decided to change the method of trying to find a new Power Supply vendor that would meet our strict requirements. This new search method required even more effect and time on Bests part. It also required we search thru hundreds and hundreds of New Power Supply vendors one by one, checking them out fully before we made 1st contact with them. Narrowing that long list of them down to a few select Power Supply vendors. Then finally making contact with the narrowed down list of New Power Supply manufactures. The 1st of 2019 we found a single very very old (20+ year) very experienced Power Supply manufacture. They again said they can meet all of our published Power supply requirements we sent them. So we sent ($$$ them using a more expensive shipping method this time) samples of the different Atari 2600 power supplies made in the last 20+ years. 2 to 3 weeks of back and forth with the new Power Supply vendor, working out items like Power Supply electrical specs, electrical certifications, label details, box details we were getting close to the point of requesting working sample / 1st article samples of the new Power supply. It came down to a few Best Power Supply requirements that the new Power supply vendor said they could meet originally, but now changed their mind and could no longer meet those few last requirements. So after months and months of working with this new Power Supply vendor, Best had to give up on them again. So Best decided to take a few months off from the new Atari 2600 power supply project and take another clean / fresh start looking for another Power Supply manufacture who could meet our exacting (but reasonable / possible to do) Power supply requirements. Best would not settle for 80% of our Power supply requirements, but only 100+%.

Early August 2019 after sorting thru more new Power Supply manufactures again

for a few more months. After weeks of back and forth, Best narrowed down the

new Power supply vendors down to two we felt could meet Bests new Auto Switching

2600 Power supply. A few more weeks of more back and forth going over each of

our new Power Supply requirement with each vendor, Best decided to go with our

final choice of PS vendor. Another two weeks of working out the final details

for each of our Power Supply requirements line by line, Best was getting to the

point of sending new sample 2600 power supplies.

Early September 2019 our new Power Supply vendor received the Atari 2600 Power supply samples we sent ($$$) them. Their Engineers started to take apart some of the samples and fully electrically test the old Atari Linear Power supply samples. Of course new questions and answers started to come up. Engineering prints on the Power supply case types, wire types, molded on strain relief types and all of the Best required changes to each Engineering prints. Next proposed sample labels (2) Artwork, Electrical Specifications, the different Power Supply Electrical Certifications sample information went back and forth for weeks.

On October 24. 2019 Best sent funds ($$) to our new Power supply manufacture for the shipping charges for their stock samples of new Auto switching Power Supplies to run our electrical and functional tests on. Once Best ran Engineering tests on the new sample stock Power supplier samples, the next step in the process was for our New Power Supplier to start to work on our extra Custom / Enhancements we required on the new Best Auto Switching Atari 2600 power supply and again new final Power supply samples for our final approval.

On November 2, 2019 our Power supply manufacture said the New samples of the stock power supplies (with a couple of the Power supply requirements Best required but not all of them) would ship to Best on November 4, 2019 for our electrical tests.

On November 7, 2019 Best received the New 1st article sample of our Power Supply manufactures recommended stock Auto switching Power supply version for the new Atari 2600 auto switching Power supply.

1st Article samples of our New Power Supply manufacture's stock made smaller plastic body Auto Switching Power supply, supplied to Best for overall electrical testing. Not all of the Best Electronics final 2600 Auto switching power supply requirements / features are on these 1st Article Power supply samples. Notice that on the longer 15 foot stronger round Power supply cable bundle is larger than the Power Supply plastic case itself. It is just the opposite on the stock Atari made OEM Power supplies with the thinner twin lead flat cable.

Right off we spotted some problem areas and a few areas we thought could be upgraded on the stock version Power Supply samples received. So they were documented for the 1st Article receiving report. Immediately we started to run electrical burn in tests (on Atari 2600 consoles running different 2600 games), thermo / temperature testing on the auto switching Power Supply plastic cases, flexing tests on the new round power cable, pull tests on both of the molded on strain reliefs and the pull tests on the heat streaked on Velcro cable tie wrap, insertion and extractions wear tests on the new Gold plated Male power connector body.

5 of the 6 US versions of the Atari 2600 old Linear Power Supplies, Best did thermo heat tests on. The left Gray Atari 2600 Power supply (35+ years old) is the one that was 1st shipped with the original generation Atari 6 switch Heavy consoles.

A bit of Atari trivia on this Gray 1st 2600 Power supply made. On the backside of this Gray Power Supply, it says / hot stamp in black letters “Atari Inc. Los Gatos, CA”. After that time frame Atari moved it’s Corp. Headquarters, Warehouses, and Assembly / Manufacturing buildings to Sunnyvale, California location. Atari had about 6 to 8+ different Far East Power supply Manufactures make the above US and International 2600 Power supply versions over the last 25+ years. The far right square version was one of the very last new US Atari 2600 Power supplies Atari made.

One of the very first Engineering tests Best did on the varies old 2600 power supply samples was the operating thermo / temperature 2600 PS case tests. We picked 6 old Atari linear 2600 models (see above picture) and a couple of the new Best Auto switching 2600 Power supplies. All 2600 power supplies were installed on 2600 consoles with a 2600 game and turned on. To reach a maxim operating Temperature each Atari game console / sample 2600 power supply was run for over 6+ continuous hours, before any case temperatures were checked. Then one by one a thermo couple wire was taped down on the top of each sample power supply and the temperatures were allowed to peak and checked / documented about 30 minutes later.

Fifth article sample of the Atari 2600 Auto Switching Power Supply box artwork.

Originally our PS Manufacture wanted Best to go with their off the shelf long rectangular shaped white thin cardboard box.

Best averaged the 6 final / peak temperatures of the old Atari 2600 Linear Power supplies. From room temperature, the Atari stock Linear Power Supply case operating temperatures increased by 24+ degrees F (the old linear 2600 power supply cases ran from warm to very warm to the touch). The new Auto switching power supply stock samples running at 110V input voltage, again from room temperature, the case temperature increased by 8 ¾ degrees only (cold / cool to the touch) or three times cooler than the old linear Atari 2600 powers supplies. Running the same Best Auto switching 2600 power supply samples at 220V input voltage, the case temperature increased by only 11 degrees (2.18 times cooler than the stock Atari OEM 2600 Linear power supplies).

One of the tests on the sample auto switching power supplies Best did was a electrical load test, to see if the 9 volts dropped when the Atari 2600 console was 1st turned on. Then the same load test after the switching power supply had been on for 4 to 5 hours, after all of the internal electrical components have come to maximum operating Temperature. Best found that sample Auto switching power supplies, (running at 110V input) the 9 volt DC out dropped down to 8.33 to 8.44 VDC and stayed there when the Atari 2600 consoles were turned on. Running at 220V, the drop was down to 8.46 – 8.55 VDC and stayed there. This DC voltage drop was not acceptable to Best and was noted the 1st article receiving report sent back to our Power Supply manufacture. Although all of the test 2600 consoles worked fine with the new auto switching power supplies samples. One of only noticeable effect, was about a ½ second or less delay on the 2600 TV game screen display when the 2600 was 1st turned on.

The next tests on the new Best Auto Switching 2600 power supply samples, was pull tests on the round cable as it goes into the 3.5 mm male connector molded strain relief. Next more pull tests were done on the round cable goes into the molded on strain relief as it goes into the black power supply case. All Auto switching power supply samples passed all pull tests and did not pull out of the molded on cable strain reliefs.

1st article label etching sample 3rd article label etching

that was rejected sample approved

Next flex tests were done on the round cables as they went into both of molded on both strain reliefs. None of the flexed round cables showed any of the typical exposed copper wires or broken internal wires damage, that the stock Atari 2600 Power supplies twin flat cables experience (see above pictures).

The 1st article stock power supply samples sent to Best, used two 24 AWG gauge wires within the outer black extruded round cable jacket. We would guess 95% of our Power supply manufactures end Power Supply Customers have gone with this same gauge wires on their power supplies. As Best has done with all of our Best upgraded Atari products like our newer beefier Best upgraded Joystick cables and the new beefier CX78 JoyPad upgraded cables, we again pushed our new Power Supply manufacture to upgrade the new Best Auto switching 2600 power supply cable. We requested (in the 1st article receiving report we sent them) that they go with an upgraded / beefier Power supply round cable. Their Engineering department reviewed our request and approved our round cable upgrade. They said they can supply the Best 2600 Auto switching Power supply with thicker stronger 22 AWG gauge wires within the black outer extruded black cable jacket. See the #7 above Auto switching power supply features. The stock sample power supplies with the 24 gauge wires within the extruded black cable jacket are extremely resistance to the Pull and Continuous flexing tests required by the different Electrical Certification agencies. The Best 2600 Auto switching power supply with the stronger / thicker 22 AWG gauge internal wires are a better / stronger / upgraded cable surpassing the different Electrical Certification agencies requirements.

Wear tests on

the

Gold

plating was on the barrel of the 3.5 mm connector was done next. Best

Engineering specification was each

Gold

plated barrel connector body must pass at least 50+ Insertion and extractions

into the 2600 PC mounted female right angle connector and show no wearing off of

the

Gold

plating at all. The insertion force tests were done using brand new (would have

the most internal spring action / tension on the new internal metal leaf

contacts and would wipe any inserted barrel connector with the maximum force /

pressure) Atari OEM 2600 jacks. Each new sample stock Auto switching power

supply barrel connectors were inserting into the new Atari 2600 female

connectors over 80+ insertions and extractions. Not a single

Gold

plated 3.50 mm barrel connectors showed any signs of the

Gold

platting wearing off or flaking off.

Close up view of one of the 1st article auto switching Atari 2600 power supply 3.5 mm Gold plated Power connector. This is one of the 1st article Best Auto switching power supply connectors that passed the Best Engineering required 50 insertions and extractions test (it was actually over tested to 80+ cycles) into a brand new Atari 2600 R/A power jacket and showed no wearing off, flaking off or any damage to the Gold plating.

Final test is a continuous (on all of the time) burn in tests on all samples of the new Best 2600 Auto switching power supplies for a couple of months. Checking them for any voltage out problems, decrease in voltage, decrease of Milliamps out (failing internal electrical components).

On October 17, 2019 the 1st article receiving report was sent to our new Power supply manufacture. It basically said the sample stock power supplies passed most of our 1st article tests (except the Best required features not on the Power Supply manufacture stock samples sent). The one feature that had to be corrected was the Auto switching load test low voltage output.

The Power supply manufacture E-Mail back the next day, said they have reviewed the 1st article report and said their Engineers will correct the low output voltage under a load problem. They said they will start to work on the final Auto Switching Power samples that will fully meet all of Bests new Power Supply documented New requirements, not on the 2 stock power supply samples they sent Best. They said they will be able send a couple of final versions of Best 2600 auto switching power supply and the Atari Power supply boxes for Best to approve.

4th article artwork sample label information to

be laser etched into the black PS inside case side.

On November 21, 2019 Best sent a second ($$$) payment to our New Power Supply manufacture for what we hoped was the final group of Best version Power supply samples. All along, sending and receiving many many E-Mails back and forth (7+ E-Mails only on the Atari 2600 Power Supply Box design and features Best required) with questions and answers regarding different final features on the Best auto switching 2600 power supplies. Another 10+ E-Mails back and forth on Laser Etched front and back Power supply label information alone.

December 14, 2019, our Power supply manufacture sent Best an E-Mail saying the 2nd article sample power supplies (made to Bests 2600 custom requirements) were being shipped to Best. On December 18, 2019 received the 2nd article sample power supplies and immediately started to run the battery of QA tests on them. The DC voltage per sample PS was up from the 1st article samples but still under the solid 9 VDC Best required. Right off Best noticed a new problem. In attempt to up the solid operating 9 VDC out / under a load Best required, our new Power Supply manufacture cased a new problem. One of the 2nd article sample power supplies when cold / 1st used, would run for 10 to 30 seconds and shut down and start up again. The second sample PS, did shut down at least once when 1st tested, but that symptom could not be duplicated on further testing. Best concluded that one or more of the new Auto switching safety features (see above 4. Auto Switching Power supply features) was causing the shut down and start up problem. When that same power supply was run for a couple of hours (all of the PS components inside got warm) the shutting down problem seemed to go away. Best sent our Power Supply manufacture an early QA receiving report before all of the tests were concluded. 3 to 4 E-Mails back and forth the PS manufacture Engineers were stumped on the early shut down problem on the one 2nd article power supply. Best told the power Supply Manufacture, that we do not have this type of shutting down problem on the Best New Auto switching 7800 power supply. The next E-Mail we received from our Power Supply manufacture was to request we ship them a couple of the new Best 7800 auto switching power supplies so their Engineers could test them and disassemble them. So on December 20, 2019 Best sent ($$) our Power Supply manufacture two of the new Best Auto switching 7800 Power supplies and the one 2nd article PS sample that keep shutting down when it was cold / 1st used.

On January 03, 2020 Best received an E-Mail from our New Power Supply manufacturing saying they had received the new sample 7800 Best Auto Switching power supplies today. Their Engineers confirmed what Best thought the early / when 1st turned on, auto shut down problem was. One of the many Auto Switching power supply safety features was causing the shut down problem. It is called Over Current Protection value. The 1st article and 2nd Auto switching power supplies were on the ragged edge of the OCP top value. When our PS manufacture Engineers pushed / redesigned the 2nd article PS internal circuits to get the voltage up to the Best required solid operating 9 VDC requirement, it pushed the 2nd article Power supply samples right up to the ragged edge of its OCP value. That is the reason why 1 of 2 of the 2nd article sample auto switching power supplies had the shutting down problem when cold / 1st turned on.

Our new PS manufacture recommended Best go with their next model up Auto Switching Power supply with a higher OCP value. They said they simply could not redesign / upgrade the 1st article / model Power supplies to meet all of Bests PS requirements. This was a minor set back on the New Best Atari 2600 Auto Switching Power supply project. It meant starting over on receiving new 3rd article PS samples, approving the larger PS case dimensions, rerunning PS case thermo tests, reworking the box artwork and other features / changes that have to go thru the sample and approval process again. But since the New PS front and back etched labels (other than the new model minor (larger) label changes), upgraded 22 AWG cable type, Gold plated 3.5 mm connector body have already been approved by Best, this third go around should go a lot faster.

Our Power supply manufacture sent Best a picture of their recommended next model up stock Auto Switching power supply for our reference, which has a slightly larger / different case style. This means the above picture of Atari 2600 box artwork would have to have the PS Picture changed and the box size enlarged / reworked.

On January 14, 2020 Best received an E-Mail from our new Power Supply Manufacture saying that they would have the new 3rd article Best 2600 Auto Switching Power supply samples by the end of March 2020.

1st article artwork that was rejected. 2nd article artwork that was accepted.

On March 10, 2020 Best received new Artwork for approval for Laser Etching on the larger model Atari Auto Switching 2600 Power supply back case.

On March 25, 2020 our Power supply manufacture sent Best a couple of pictures of the newly Etched

samples of the larger Auto switching 2600 PS front and backside cases.

Our PS Manufacture production department

said they had to slightly reduce the overall

size of the Atari Name and Logo compared

to the above approved artwork, because of

limits of the Laser Etching machine.

On March 26, 2020 we received on E-Mail saying our PS Manufacture was shipping 2 new samples of the larger case 2600 Auto switching power supply samples to Best.

April 04, 2020 Best received the latest larger sample of the Atari 2600 auto switching power supplies. We immediately started to test them.

Top on the lists of tests on the new sample PS was the electrical tests. All new sample PS seemed to have corrected the low output voltage (under 9 VDC) problem (on the smaller 1st article PS samples) at 110V and 220V input voltages. But further testing a new problem showed up. On the Atari 2600A and 2600Jr. (newer designed 2600 motherboards that are more power efficient) Atari consoles the new PS samples output voltages at 110VAC / 220VAC were between 9.19 to 9.20 VDC out when the 2600 consoles were running 2600 games. But on the older 1st Generation (less power efficient) Atari 6 switch 2600 consoles the output voltages were still at 9.10 to 9.13 VDC (110VAC) and 9.09 VDC (220VAC) which are all acceptable ranges. The output voltage on the 2600 6 switch motherboard on board 7805 Voltage regulator (drops input voltage from 9 - 14 VDC down to a solid 5 VDC, which the 3 Atari 2600 chips require to properly run), dropped down to 4.97VDC which would work fine on all Atari 2600 consoles made but was not acceptable to Best. On the newer 2600A and 2600Jr. the voltage out of the 7805 voltage regulator was a solid 5.06VDC (at 110VAC and 220VDC input voltages) which is acceptable and within the normal operating range for any Atari made 2600 console. So Best sent an early 1st article preliminary report to our PS Manufacture on this new voltage problem.

Next test Best did was the thermo operating PS case temperature tests. Again to reach a maximum operating case Temperature each new sample larger PS case was run (connected up to a running 2600 console) for over 6+ continuous hours, before any case temperatures were checked with a thermo couple. Operating at 110VAC the new PS larger case temperature only raised up 7 degrees F. (cold / cool to the touch,1 1/2 degrees less the smaller 1st article PS sample case temperature raise) over normal room temperature. At 220VAC the PS case temperature raised up the same 7 degrees F. Compared to the stock Atari older linear power supplies (running at 110VAC) case temperature tests that raised up over 24 degrees F. (ran from warm to very warm to the touch).

Several E-Mails back and forth between Best and our PS manufacture Engineers, they were stumped with this type of auto switching power supply low voltage out problem after the 2600 7805 voltage regulator. Basically their newer Electrical Engineers have never came across this type of older product (that used linear power supplies) type of power problem. Their Engineers only suggestion was to modify the millions and millions of Atari 2600 6 switch consoles world wide, so they would work with the new auto switching power supply. Best told them this was not a real world option.

Best came to the conclusion that an off the shelf Auto switching Power supply would not work with all of the different Atari 2600 consoles. Most new auto switching Power Supplies are designed to work with newer state of the art products with fixed operating voltages / power requirements and set electrical / electronic specifications which they work fine on. The very old 35+ year old Atari 2600 six switch consoles, the newer 25+ year old Atari 2600A 4 switch consoles and the newest 15+ year old 2600JR consoles all have slightly different power requirements (ranging from the very 1980 Power Hungry 2600 6 switch consoles, a little more power efficient / newer 2600A consoles and the last 2600Jr consoles that was a state of art (back then) designed power efficient motherboard design / circuits / chips. The standard off the shelf older inefficient power hungry fixed linear (110V or 220V) power supplies can handle this wide range of power requirements. But the new power efficient Auto switching power supplies have a hard time with this wide range of power requirements.

More E-Mails back and forth with our PS Manufacture, Best came to the conclusion that we had to send our PS Manufacture all three Atari consoles to them, so their Engineers can see the problem and design a custom made Auto Switching Power supply to meet our Atari 2600 consoles world wide requirements. So on April 09-20 Best sent ($$) the 3 Atari 2600 consoles / models to our PS manufacture for their analyses.

By the way, in preparing the sample 2600 consoles / motherboards to ship out, Best found another Atari 2600A motherboard that had the same low voltage 4.97VDC after the 2600A 7805 voltage regulator problem as the 2600 6 switch test consoles.

In a normal world, the Atari 2600 models we sent to our Far East PS manufacture should of arrived in about a week and half. But because of the COVID-19 virus and the world wide shut down (very few international planes flying to the Far East and nobody working at all) that time frame stretched out to close to 3 months. According the to Tracking information the package got caught up in the Customs department.

On June 6, 2020 our PS manufacture said there was a problem with the shipment we sent them. They said we declared one item as a used 2600 game cartridge. The Far East Customs department said that is a restricted item. Our manufacture tried to explained to them that the used game cartridge only worked

on the 30+ game consoles. But there was there was no changing their minds. They said that they are going to return the package back to Best.

June 19, 2020 the sample 2600 motherboards were received back from the Far East. On June 22, 2020 Best again sent the Atari 2600 motherboards back to our PS supplier using a more expensive ($$$) shipping method / company. This time we declared the 2600 motherboards, game PCB (we removed the 2600 game cartridge plastic case) and only shipped the game PCB board only, as 5 used PCB boards.

Positive start, on 06-24-20 we received by E-Mail from our Far East PS Manufacture that they were notified by the Shipping company, that they had a package coming in from Best Electronics. They had fill out some required incoming Customs Forms (and contacted Best for more details on the shipment) to speed up the delivery process to them.

On June 30th we got in a E-Mail in from our PS manufacture. They had received the 3 Atari 2600 game consoles. Since none of the PS Engineers had even seen the1st Generation Atari 2600 game consoles, they had questions on how to put them together (2600 6 switch, 2 PCB board set) and how to properly install the game cartridge into the 2600, 2600A and 2600JR consoles, before they started to run their Engineering Electrical tests on them. Best sent them full complete instructions on to how to assemble and properly run the 2600 game consoles. We pointed out to their Engineers, that the 1st Generation Atari 2600 6 switch and 2nd Generation 2600A consoles had the low voltage out of the 7805 voltage regulator problem, so they could test / duplicate this problem in their Electrical Engineering lab.

On July 17, 2020 we got an E-Mail in from our PS Manufacture saying their busy Engineers finally got to testing of our samples. The sample US Atari 2600 Power supplies we sent them were between 5 to 30+ years old and were from 5 to 7+ completely different Far East PS Manufactures. They give us their initial report on the Atari 2600 power supplies on the Atari 2600, 2600A and 2600JR motherboards. To say the least it really surprised us (that does not have that often, in the last 40+ year in the Atari business). Their highly accurate (out to 5 digits) lab quality (out to 3 digits) Fluke Digital Test equipment (showed their 2nd generation auto switch power supply sample was showing 4.95 VDC (at 110V voltage input) after the 2600 and 2600A 7805 motherboard voltage regulators, which Best knew and one of the reasons why we sent the samples to our PS manufactures. The true shocker for Best was even the 5 to 6 various Atari stock OEM 110V 2600 Power supplies also tested / showed 4.95 VDC on the 2600 and 2600A motherboards. All of the analog, needle sweep (during the early years of Best Electronics) and then later newer digital test equipment was either not that accurate or were all were simply rounding up to 5 VDC the voltage readings we took off all of the hundreds and hundreds of 2600 motherboards we have tested or repaired over the last 36 years.

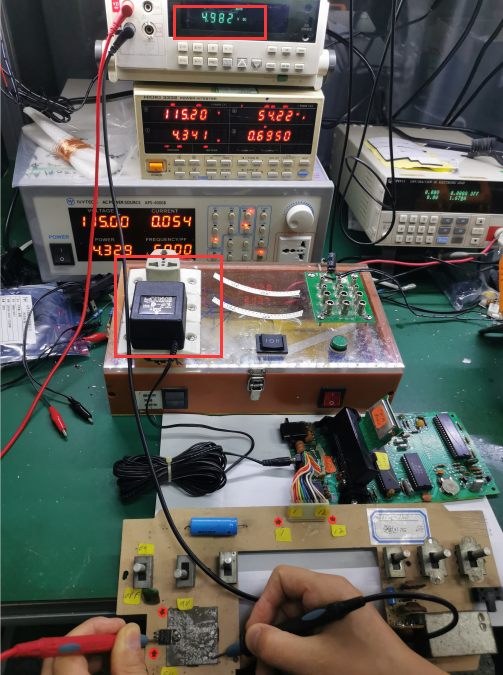

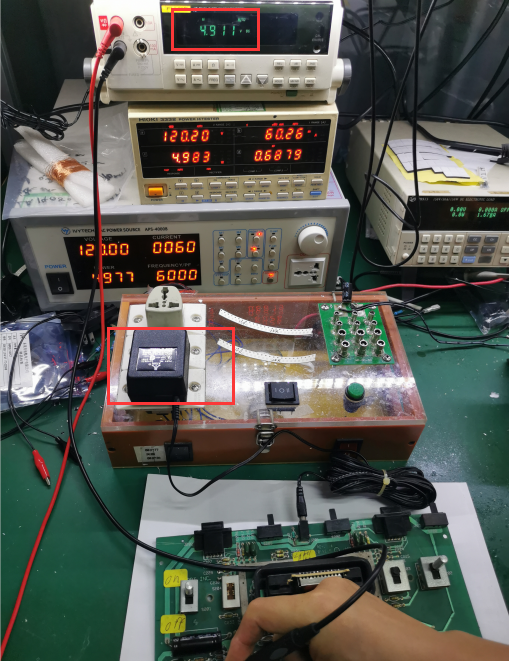

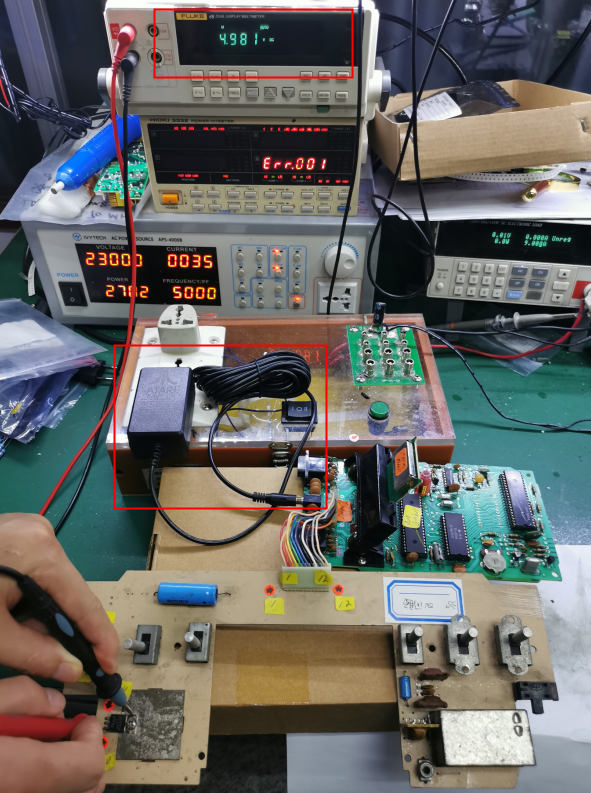

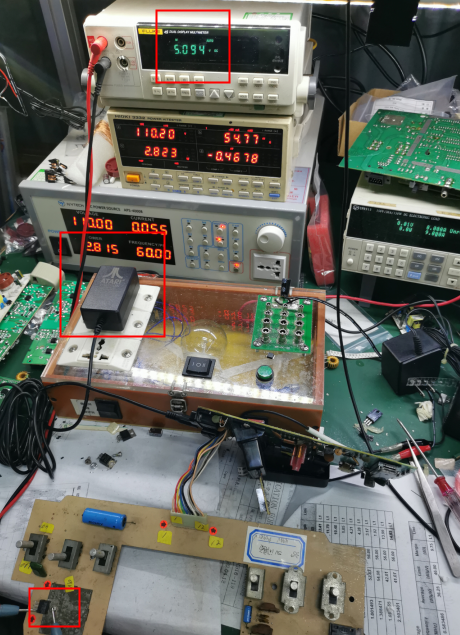

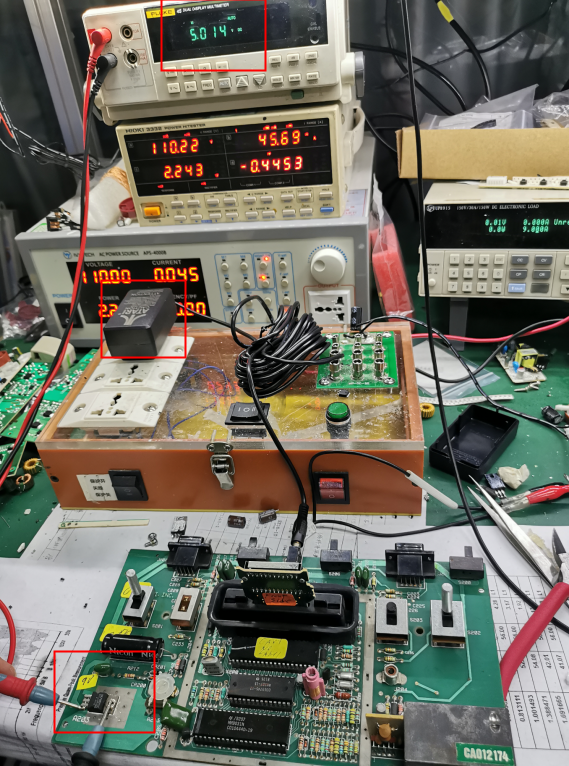

The following pictures are from our new Power Supply Manufacture Tests they ran for Best. They sent over 40 different Test pictures, here are few of the highlights.

Atari OEM 2600 Linear PS running at 110V Atari OEM 2600 Linear PS running at 120V

AC on an Atari 2600 6 switch console. AC on an Atari 2600A console. 7805

7805 Voltage out was 4.982 VDC. voltage out was 4.911 VDC.

Atari OEM 2600 Linear PS running at 110V

AC on an Atari 2600Jr console. 7805

voltage out was 5.089 VDC

New Best Auto Switching 2600 PS running New Best Auto Switching 2600 PS running

at 230 VAC on an Atari 2600 console. at 230 VAC on an Atari 2600Jr console.

7805 voltage out was 4.981 VDC. 7805 voltage out was 5.090 VDC

New Best Auto Switching 2600 PS running New Best Auto Switching 2600 PS running

at 110 VAC on the same 2600 console at 110 VAC on the same 2600A console

with a new 7805 voltage regulator installed. with a new 7805 voltage regulator installed

5.094 VDC out of the 7805. 5.014 VDC out of the 7805.

The last generation more Power Efficient Atari 2600Jr. motherboard design,

was most likely a CAD designed / had CAD laid out motherboard circuit

traces. The original (35+ to 20 year old) less Power Efficient Atari 2600 6

switch and early 2nd generation 2600A motherboards were most likely a

hand drawn / hand laid out motherboard circuit traces.

Another mystery and another reason why we sent the samples to our Manufacture was their auto switching power supply running at 220 / 230 input voltage was showing a true 5 VDC out on all three 2600 motherboards. So we asked the Engineers to look into to this difference and see if they could correct this problem at 110V input voltage on their auto switching power supply sample.

After the 1st Test report we asked our PS manufacture to run a second group of tests. July 19, 2020 we got the second test report. Best noticed that PS Test engineer used the wrong PS sample we sent them. He pulled a sample of the new Best Auto switching 7800 Power supply that was running at 9 VDC at 1 Amp. So the second tests were invalid. We asked them to run a third group of PS tests using some of the very oldest (30+ year old) 2600 PS samples we sent them.

On July 21, 2020 Best received the 3rd group of PS Tests. Essentially the test results were the same as the 1st test report.

Best did some more research into the old Atari 2600 linear Power supplies. On July 22, 2020 we asked our PS manufactures to make a change to their Auto switching power output voltage and amperage and run a 4th and final group of Engineering tests for us. Basically the test results did not change

The time on this new Best 2600 Auto switching power supply project has been stretched out even longer because of the World Wide COVID-19. After a couple of months of complete shut down of the their PS manufacturing plant, for the rest of the 2020, they were running a much reduced Production / Engineering staff.

On August 05, 2020 our PS Manufacture said because of the problems on this new PS, they were

assigning their Senior PS Engineer to this project.

On August 13, 2020 we got in an E-Mail saying the Senior Engineer thinks he found the problem. He said the problem between the 3 different 2600 motherboards / consoles was with the 7805 voltage regulators themselves. Either the original manufacturing tolerance (+ or - output voltage range) on the voltage 7805 regulators was off or the 15 to 30+ year old / well used 7805 voltage regulators were starting to fail and output was less than true 5 VDC. This is something Best would not even considered. All of the 7805 Voltage regulators on all of the Atari products for the 40+ year have always consistence with the 5 volts out. They found this problem by moving the 3 different 7805 voltage regulators to different 2600 motherboards. The low voltage out (under true 5 volts DC) problem, seem to follow each changed 7805 voltage regulators to the different 2600 motherboards.

Best did a little research on this 7805 tolerance theory. To prove / verify their theory before we went into full production on the New 2600 Power supply, on August 18, 2020 we sent ($$) Express Mail to our PS Manufacture 3 different manufactures of 7805 voltage regulator groups we had in stock. Two different date codes from National Semi Conductor, single date code Gold Star and Texas Instruments 7805 voltage regulators. Best felt these different new 7805 regulators from different manufactures would fully test the low voltage out tolerance problem theory.

On August 29, 2020 we got in an E-Mail in from our PS Manufacture saying they had received the new 7805 Voltage regulators we sent them. Their Engineers put the 4 different lots of new 7805 on the Atari 2600 motherboards. To Bests surprise all 2600 motherboards now showed a true 5.03 to 5.08 volts out with the different manufacture new 7800 regulators. So this new test results, disproves Best's theory and test results that some of (not all) the older designed Atari 2600 6 switch and 2600A motherboards (but the newer designed power efficient 2600Jr motherboards) were power hungry and the new auto switching power supplies could not handle the power input requirements. So now we gave our PS manufacture the go ahead to finish up on the last details on the new Atari 2600 Auto switching power supplies, so we could get them finally on order.

For the next few months Best and our PS Manufactures spend wrapping up the final details on the new the new Atari auto switching 2600 Power supplies. Details like final new box artwork and box wall thickness with the larger version 2nd article Auto switching power supply picture, a few text changes on the box artwork, exact box shape (after all of this time and work, our PS manufacture was still pushing their stock size and shape of box, which Best rejected) and final custom made Atari 2600 box shape / style. Another detail that seemed to slip between the cracks of the months of work, was the exact type of Velcro cable tie wrap Best required and how it was heat staked / attached / bonded to the 2600 PS round cable. The final recap was to review all of the months Power Supply details Best had been discussing with our Power supply.

On December 2, 2020 after 16+ months working with our present new Power Supply manufacture on the Best auto switching Atari 2600 power supply, we sent the funds to our manufacture to start to produce them. A few days latter they got back to us to say that the normal production time to produce the new Best 2600 Auto switching power supplies had been stretched out because of several shortages of the few components that are required to make that Auto switching power supply series. They were forecasting early 2021 delivery.

Final approved new larger box Power

Supply art work, received on 12-24-20.

On January 30, 2021 Best got in an E-Mail from our new Power Supply manufacture that our new Atari 2600 Auto Switching power supply were ready to ship to us.

Caller ID # required on all phone calls to Best

Current Pacific Standard Time is:

Because of the big volume of Spam E-Mails we receive everyday, we had to install E-Mail Spam filters on our server. When sending an E-Mail to Best, Please put the word "Atari", Atari item or Atari part number, Atari Question or Atari Sales inquiry in the Subject line. E-Mails with the typical Spam subject matter like: Urgent, Must read, Regarding, FWD, HTML Code, Blank subject line (RE:) or other SPAM E-Mail Subject lines you receive, will be automatically deleted on our E-Mail Server and never reach us.

After sending your E-Mail to us, if you do not hear back from us within a day or less, please resend your E-Mail inquiry with a different Subject matter information or from a different E-Mail address. We do

100% respond to every Atari E-Mail we receive. But sometimes Spam Filters on your Internet Service Provider or your own personal E-Mail Spam software filter you have installed may delete or send our return Atari E-Mail to your Trash can.